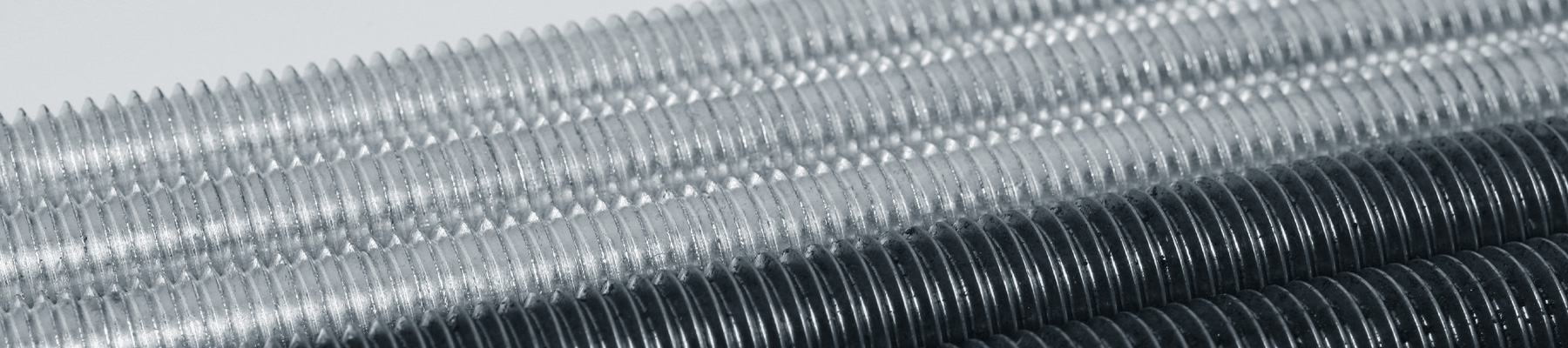

ISO 898-1 Grade 10.9, 12.9 Threaded Rod

Key Points of ISO 898-1 Threaded Rods:

Application: Commonly used in automotive manufacturing, machinery, construction, wind energy, and other heavy-duty applications requiring high tensile and yield strength.

Materials: Typically made from medium-carbon steel or alloy steel, quenched and tempered to achieve high strength.

Grades: ISO 898-1 covers multiple property classes (4.6, 8.8, 10.9, 12.9, etc.), among which Grade 10.9 and Grade 12.9 represent the strongest categories.

Testing Requirements: Fasteners must pass mechanical property tests including tensile strength, yield strength, hardness, and impact resistance to ensure safety and durability.

| 01 ISO 898-1 Grade 10.9 Threaded Rod | Material: Alloy steel, quenched and tempered. Tensile Strength: Minimum 1040 MPa. Yield Strength: Minimum 940 MPa. Applications: Widely used in automotive parts, construction equipment, and heavy machinery where high load-bearing capacity is required. Temperature Range: Suitable for service up to about 300°C. Properties: High tensile strength with excellent toughness. Good fatigue resistance for dynamic load applications. Cost-effective option compared to Grade 12.9 while still offering strong performance. |

| 02 ISO 898-1 Grade 12.9 Threaded Rod | Material: Alloy steel, quenched and tempered, with higher alloy content compared to 10.9. Tensile Strength: Minimum 1220 MPa. Yield Strength: Minimum 1100 MPa. Applications: Critical fastening in aerospace, automotive (engine components), heavy machinery, and tooling where maximum strength is essential. Temperature Range: Typically used up to 300°C. Properties: Superior strength and hardness compared to Grade 10.9. Excellent performance under extreme stress conditions. Less ductile than lower grades; more brittle in some environments. |

| Feature | ISO 898-1 Grade 10.9 Threaded Rod | ISO 898-1 Grade 12.9 Threaded Rod |

| Material | Medium-carbon/alloy steel, quenched & tempered | Higher-alloy steel, quenched & tempered |

| Tensile Strength | ≥ 1040 MPa | ≥ 1220 MPa |

| Yield Strength | ≥ 940 MPa | ≥ 1100 MPa |

| Corrosion Resistance | Limited (requires coating such as zinc, HDG, black oxide) | Limited (requires coating) |

| Applications | Automotive, construction, machinery | Aerospace, tooling, high-stress machinery |

| Temperature Range | Up to ~300°C | Up to ~300°C |

| Cost | More economical | Higher due to strength requirements |